DPSM pull out all the technical stops

In Béziers, as part of the rehabilitation of a section of the town’s sanitation network.

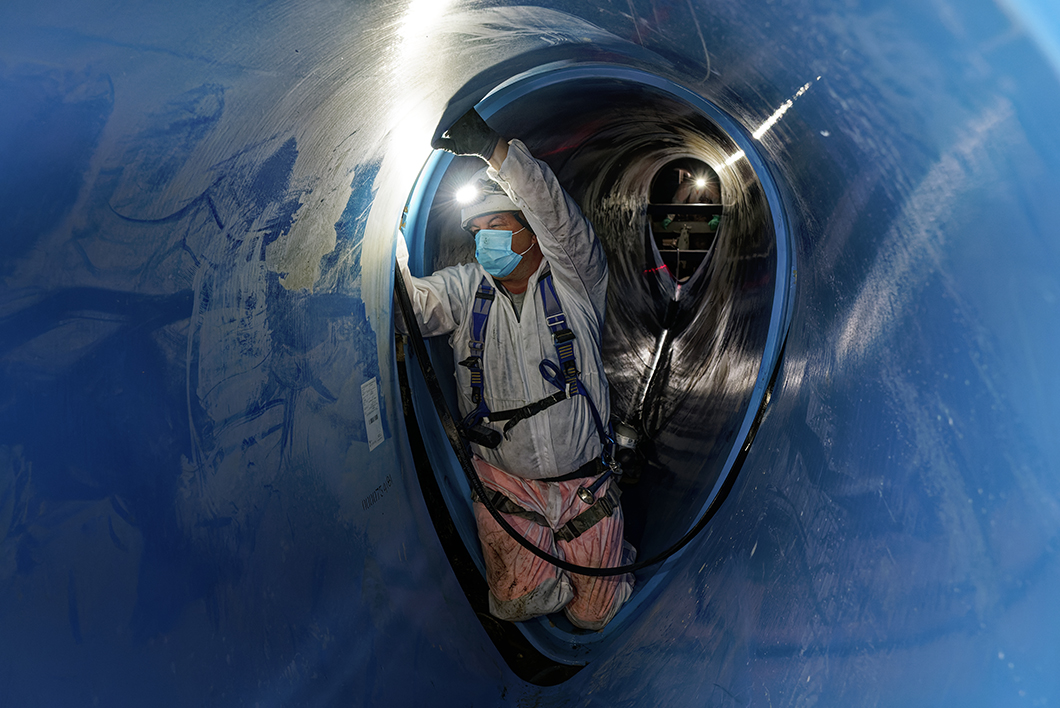

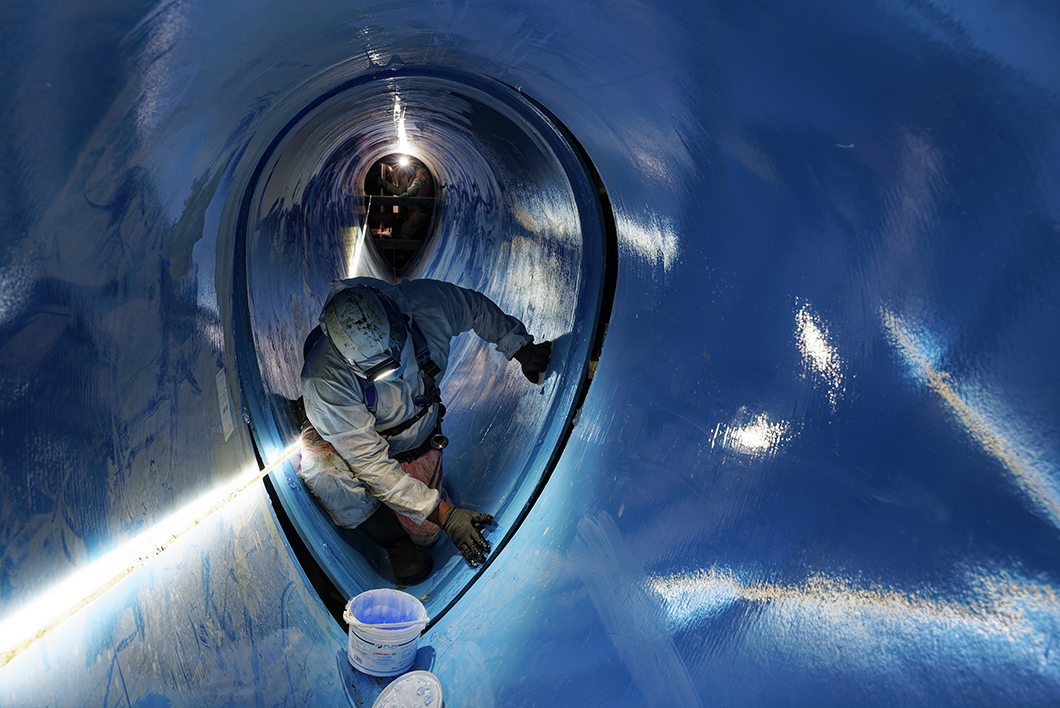

The Béziers Méditerranée Urban Authority has accepted DPSM’s solutions for the rehabilitation of a visitable segment of its sanitation network located right next to the mainline rail station and partly beneath its tracks.

A strategic but congested main sewer

This section is part of a mains sewer that transports just over half of all the town’s wastewater. A fact that led to the installation, during the works, of a by-pass with a capacity of 600m³/h. The DPSM teams extracted 47m³ of gravel and other waste material from the poorly maintained section – an unpleasant prerequisite when it comes to rehabilitation projects.

Double whammy

The 150m stretch concerned is 2m high and 1m wide, but its composition is not at all uniform. An ovoid of concrete poured on site makes up 100m, while the remaining 50m, below the train tracks, are an inverted U made of cut stone. So, two sections that, apart from grout injections, required different treatments.

Grout injections all round

Once cleaned, the 150m to be rehabilitated underwent grout injections, also known as chemical grouting. The aim of this is to fill any gaps there may be between the structure and the ground it rests in. So, 35m³ of grout, mainly consisting of bentonite and cement, were injected along the 150m section via a series of 4 canulae and 1 blowhole located every 1.5m.

Innovative structural mortar

The side walls and arch of the 100 m ovoid were then wet-sprayed with a 6 cm-thick (80 tonnes, in total) coating of an innovative mortar. Certified, damage-resistant and sufficiently structural without having to pre-install a welded wire mesh, it speeded things up considerably and made them substantially less onerous. As for the apron, this was reprofiled (using XA2 concrete) and recovered with an abrasion-resistant mortar.

U know it makes sense

To account for the worst-case scenario in terms of load on the SNCF tracks, i.e. 2 freight trains crossing at the same time (20,000 t), 12 of the 50m located under the rails were reinforced with GRP liners and the interstitial gaps were injected in 3 phases – the last one carried out at night with a quick-drying grout while train traffic was halted. The remaining 38m, upstream and downstream of the liners, were treated the normal way, i.e. mortar sprayed over welded wire mesh.

For this job, DPSM was able to propose and use a series of different techniques suitable for the complex layout of the structure to be rehabilitated. It is an excellent showcase for its expertise in rehabilitating visitable structures.